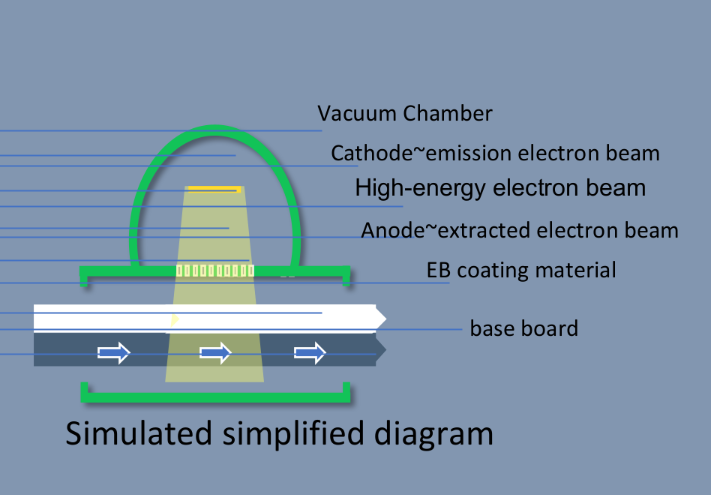

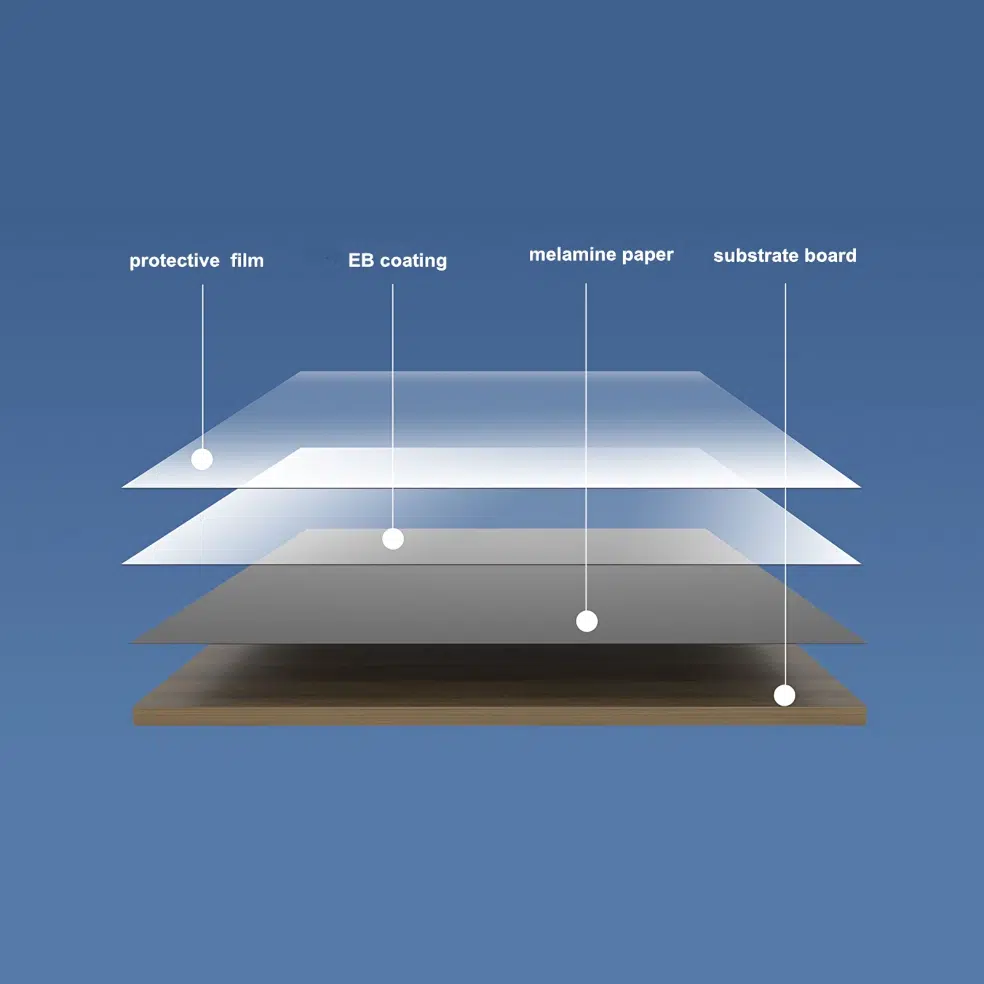

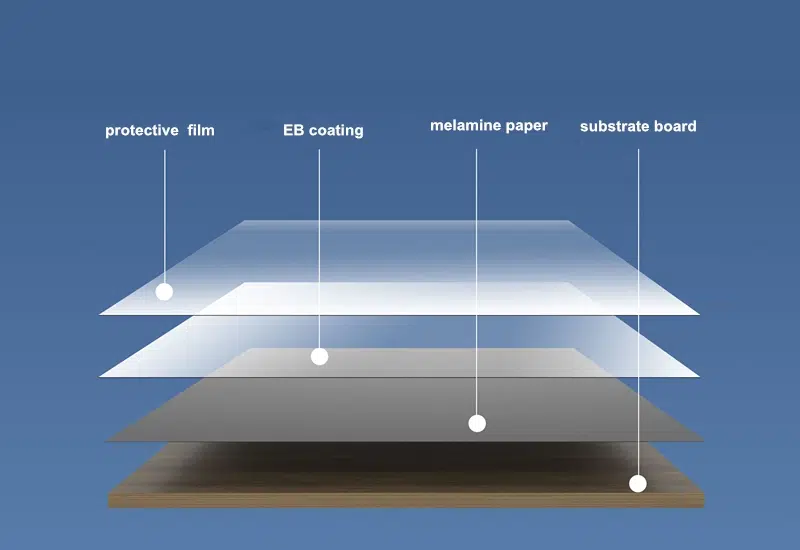

EB is short for Electron Beam Curing. Electron acceleration produces a beam of high-energy electrons approximately equal to the beam of light-energy material, using a fast emitter to be processed the surface, forms a functional coating onto the board.

Features of Electron Beam Curing:

High-End Decoration New Doctrine: Empowering furniture with high technology.

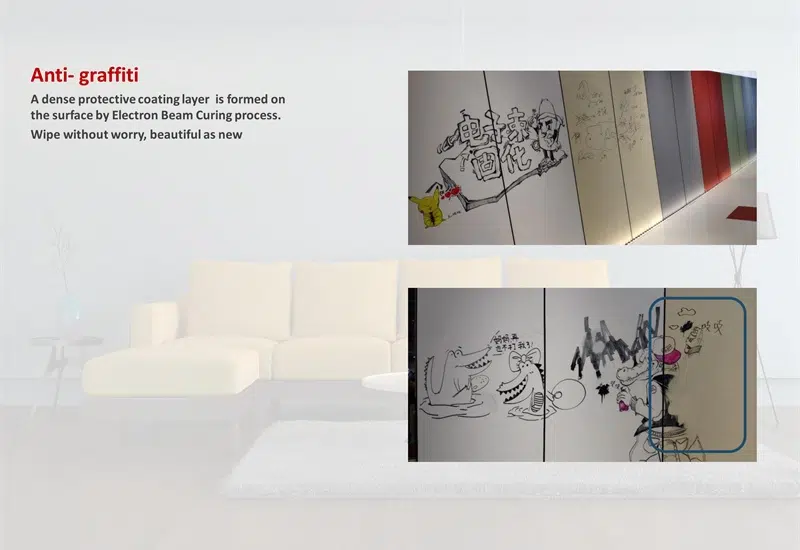

In a short word, EB boards use electron beam coating onto the board surface, Thereby forming a functional layer, that upgrades the appearance and performance of the board completely.

Each series substrate board can be: MDF board, plywood board, particle board, OSB board

Property | PET film | EB film |

Structure | 3 layers | 4 layers |

Material Compensation | G +APET+APET | G+APET+APET+G |

Surface Treatment | Excimer coating | EB Curing |

Hardness | 2H | 3H |

Impact Resistance | 1 | 2 |

Anti yellowing | 3-5 Years | 8-10 Years |

Antibacterial | No | Yes |

Chemical Resistance | No | Yes |

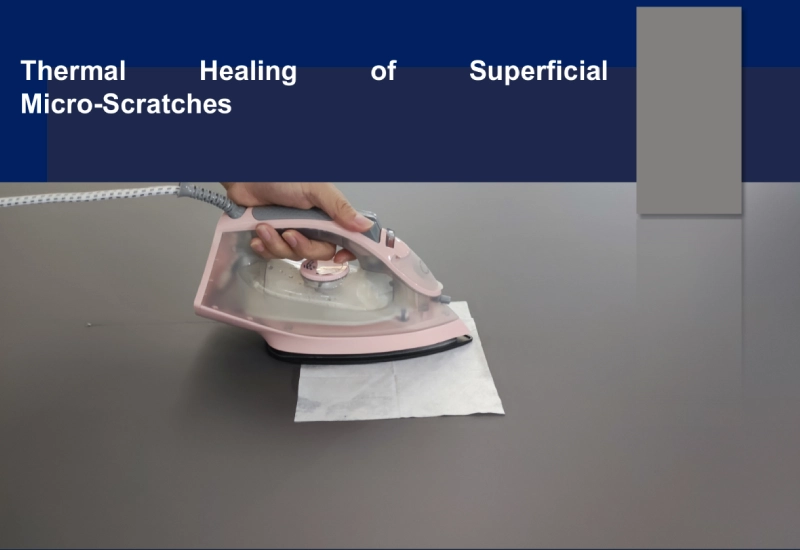

Micor Scratches Hot Repair | No | Yes |

Heat Resistance | Yes | Yes |

Anti-fingerprint | Yes | Yes |

Eco-friendly | Yes | Yes |

Stain Resistance | Yes | Much more easy to clean |

Capturing the Essence of Colour

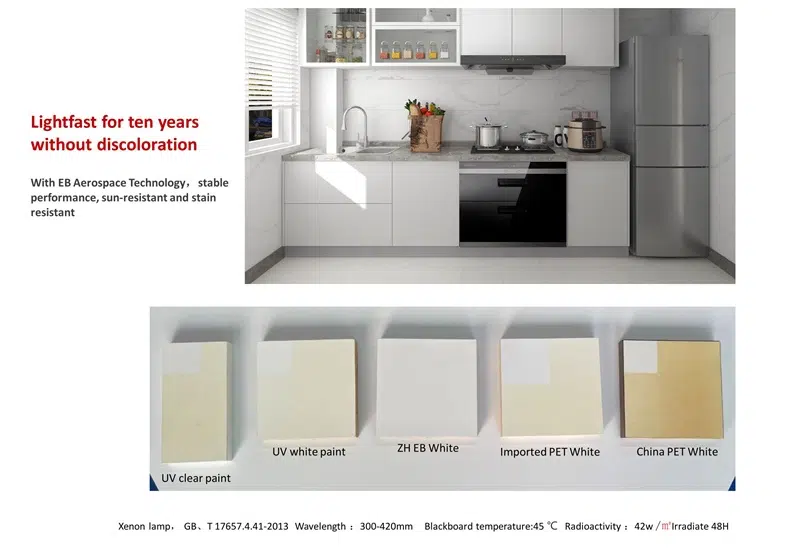

Long-lasting, retains its beauty

No fingerprints left behind

Last for ten years

Sun-resistant and Stain-resistant

Antimicrobial make it smell proof.

EB MDF board size: 1220*2440 / 1220*2745MM, thickness: 18MM, Substrate board can be: MDF board, particle board, plywood board, OSB board, etc. Application: furniture doors, kitchen cabinets, wardrobes, furniture, doors, wall panels, etc.